Electron

Manufacturing

26 Aug, 2022

$69,63,400

58 Danc Street, USA

Got questions or need assistance with your Industry needs?

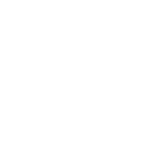

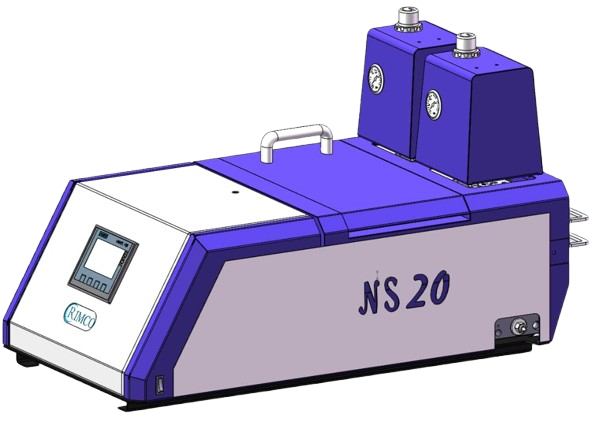

Liquid Painting Application Booths are used across various industries and are engineered to be compatible with different types of liquid paints. These spray booths provide a controlled environment for efficient, precise, and high-quality paint application, ensuring optimal finishing results for all types of parts.

Systems suitable for intensive use in which paint particles are filtered by interacting with water.

Systems that retain paint particles using filter materials and do not use water.

Rooms designed to provide the painting environments required by the application.

Suitable solutions for continuous or single piece production processes.

Different material options for durability and long-lasting use.

Heat control to ensure ideal painting temperature and fast drying processes.

Insulation and energy-saving equipment that contributes to energy efficiency.

Environmentally friendly operations in line with European standards.

Liquid Paint Application Booths are ideal for applying non-stick and ceramic coatings, including solvent-based and water-based paints, primers, topcoats, and specialty finishes. When integrated with optional modules like flash-off chambers, positive pressure chambers, and curing ovens, these booths form complete, customized painting systems tailored to meet specific production needs. These advanced systems not only enhance painting efficiency and product quality but also help reduce overall operating costs, making them a valuable solution for industrial coating applications.

A liquid painting application booth is a controlled environment designed for applying various types of liquid paints, including water-based, solvent-based, and specialty coatings, to parts or products.

These booths support a wide range of paints, including solvent-based paints, water-based coatings, primers, topcoats, non-stick coatings, and ceramic paints.

Liquid painting booths are used in automotive, aerospace, metal fabrication, furniture, electronics, and many other manufacturing industries that require high-quality painted finishes.

Yes, booths can be tailored with additional modules such as flash-off chambers, positive pressure rooms, and curing ovens to meet specific production needs.

Booths come in various sizes to accommodate small parts to large industrial equipment. Custom sizing is also available based on your workspace and product dimensions.

Smart Engineering is your reliable partner for industrial finishing and hot melt dispensing solutions. With more than 15 years of experience, we specialize in supplying, installing, and maintaining powder and liquid coating equipment, as well as hot melt adhesive systems.

Copyright © 2020 – 2025. Smart Engineering. All Rights Reserved. SEO Powered by Mohamed Aasik.

WhatsApp us