Electron

Manufacturing

26 Aug, 2022

$69,63,400

58 Danc Street, USA

Got questions or need assistance with your Industry needs?

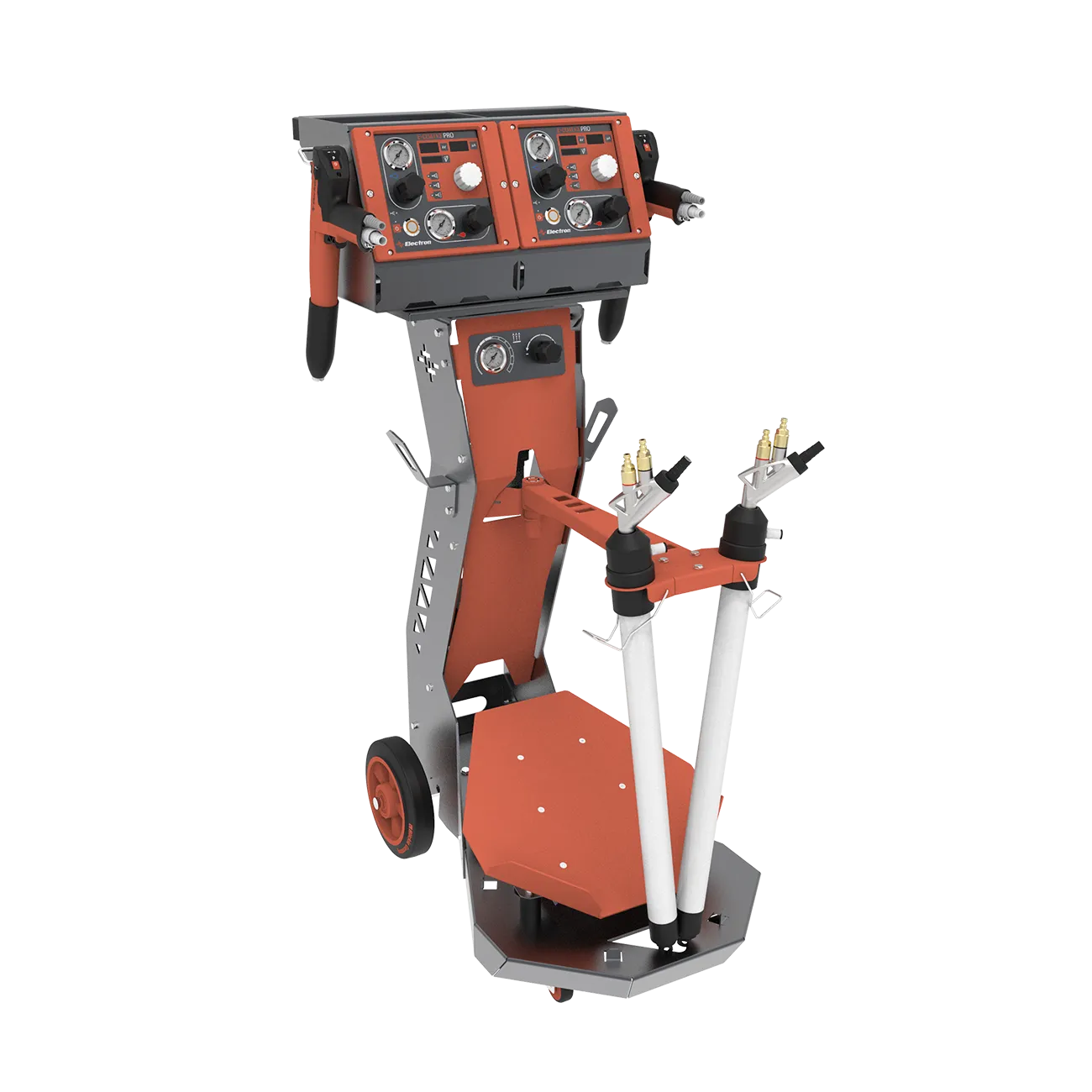

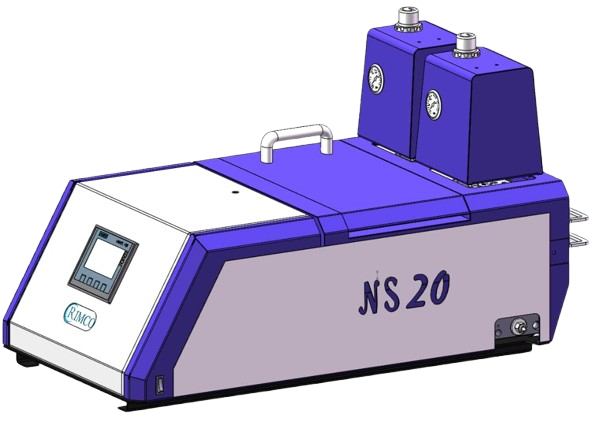

E-COAT+ 3 PRO Series represents the entry-level range of devices where pneumatic and electrical parameters are controlled directly via buttons and regulators on the front panel.

Its electrical controls allow independent adjustment of air values while managing voltage and current. With factory settings and 50 customizable electrical presets, the E-COAT+ 3 PRO stands out as a cost-effective solution, particularly suited for manual and basic applications. It also supports a variety of application needs through its automatic and manual modes, along with a broad selection of compatible accessories.

With factory settings and 50 customizable electrical presets, the E-COAT+ 3 PRO offers an economical solution, ideal for both manual and basic applications. Designed to meet diverse application needs, it supports both automatic and manual modes and is compatible with a wide range of accessories.

Electrical controls provide the opportunity to adjust air values independently of each other while connected to voltage and current.

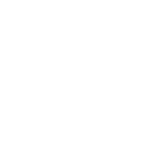

MANUEL PRO SET WITH VIBRATORY BOX FEED

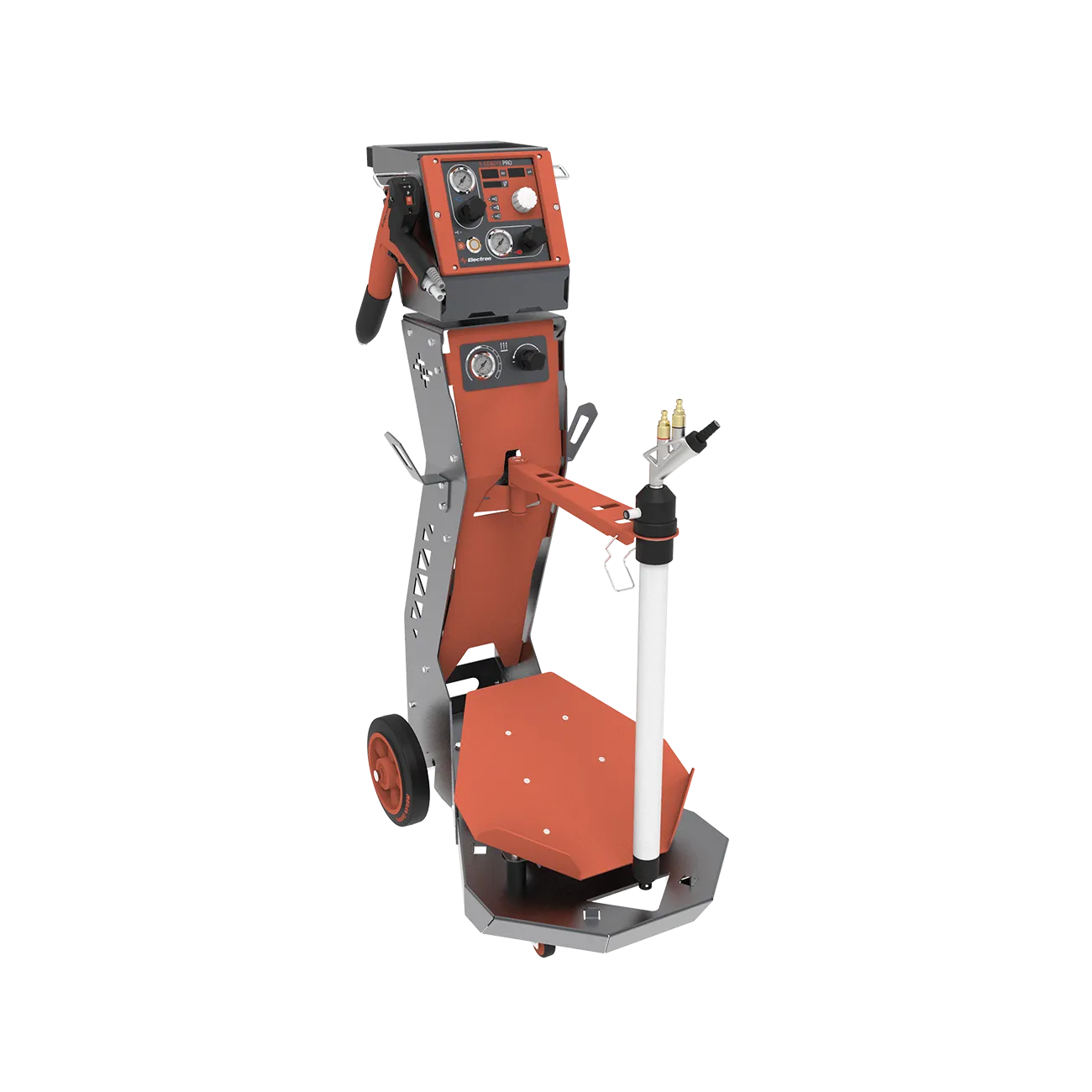

DUAL MANUEL PRO SET WITH 50LT HOPPER

DUAL MANUEL PRO SET WITH VIBRATORY BOX FEED

AUTOMATIC PRO EQUIPMENT BARE KIT

E-COAT+3 PRO Series is an advanced electrophoretic coating system designed to deliver superior corrosion resistance, uniform coating thickness, and excellent surface finish for metal components.

It is ideal for automotive, heavy machinery, electronics, appliance manufacturing, and general metal finishing industries.

Yes. It meets most global environmental standards, including RoHS and REACH compliance. The low-VOC, heavy-metal-free formulation reduces ecological impact.

It is suitable for steel, galvanized steel, aluminum, and other conductive metal substrates.

Typical curing is at 170–180°C for 20–30 minutes, but this may vary depending on part geometry and coating thickness.

Smart Engineering is your reliable partner for industrial finishing and hot melt dispensing solutions. With more than 15 years of experience, we specialize in supplying, installing, and maintaining powder and liquid coating equipment, as well as hot melt adhesive systems.

Copyright © 2020 – 2025. Smart Engineering. All Rights Reserved. SEO Powered by Mohamed Aasik.

WhatsApp us