At Rimco, we deliver more than just machinery – we provide dependable hotmelt solutions that keep your production running smoothly. Our systems are designed with your business in mind, combining innovation, durability, and ease of use.

Designed to integrate seamlessly with most hotmelt units, making upgrades simple and cost-effective.

Engineered for precision and consistency, ensuring strong, lasting bonds every time.

Faster melting technology minimizes downtime and maximizes adhesive performance.

Intuitive controls and straightforward setup reduce operator training time.

Built with high-quality components that ensure long service life with minimal maintenance costs.

The only specialized hotmelt machinery manufacturer in the Middle East.

Backed by over 15 years of technical expertise in industrial gluing solutions.

Machines tailored to meet unique industrial requirements.

Installation, training, spare parts, and after-sales service to keep operations smooth.

Manufactured to meet international quality, safety, and performance benchmarks.

Experience the Rimco difference. Choose our innovative hot melt gluing systems and take your production efficiency, product quality, and cost savings to the next level.

| Feature | Specification/Detail |

|---|---|

| Pump Type | Pneumatic & Gear Pump |

| Controller | Siemens PLC & HMI touchscreen |

| Melt Rate Options | 4 kg, 7 kg, 10 kg, 15 kg, 20 kg, 30 Kg, 50 Kg & 100 kg per hour |

| Temperature Range | 40–230°C |

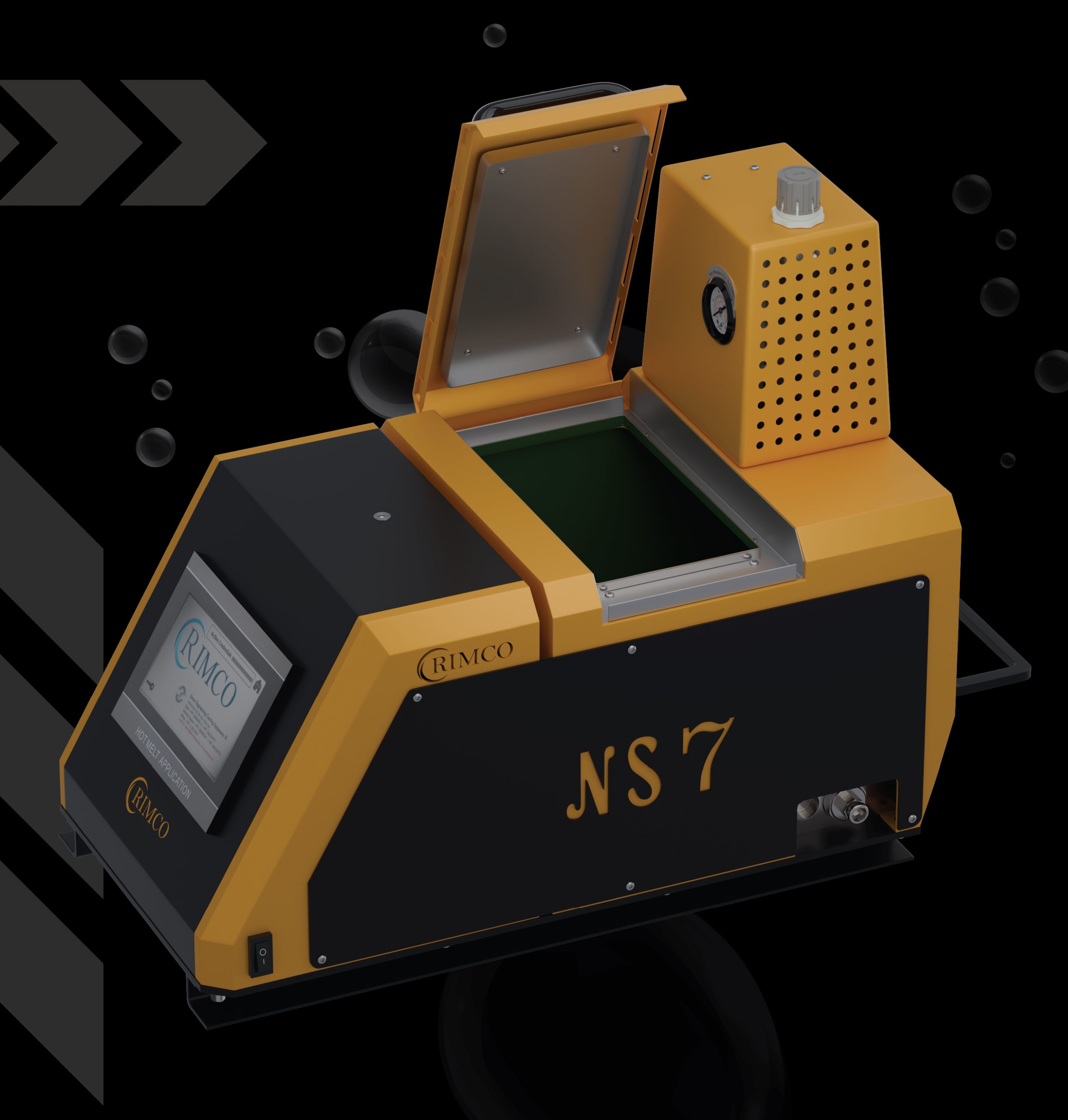

The Rimco Nseries Hot Melt Unit with gear pump system is engineered for efficient, reliable, and precise adhesive dispensing in industrial environments. Now equipped with a Siemens PLC controller and user-friendly HMI touchscreen, this system ensures advanced control, seamless integration, and easy operation for packaging, assembly, and manufacturing lines.

The high-quality gear pump provides a steady, reliable flow of hot melt adhesive, ideal for applications requiring uniform bonding and consistent output.

Advanced Siemens PLC controls paired with a user-friendly HMI touchscreen allow for intuitive operation, easy parameter adjustments, and real-time system monitoring. Password protection and clear status indicators further simplify day-to-day use and maintenance scheduling.

Maintains adhesive temperatures between 40°C and 230°C, ensuring optimal adhesive performance and preventing charring or degradation.

The system supports multiple hoses and applicators, making it adaptable to various production line configurations and easy to integrate with parent machines.

Our process is designed to maximize efficiency and quality at every stage of production. By integrating advanced technologies and best practices, we ensure seamless workflows.

The robust piston pump generates high, consistent pressure, ensuring smooth adhesive flow even with thick, high-viscosity materials or complex, multi-applicator setups.

Advanced Siemens PLC controls combined with a user-friendly HMI touchscreen make operation simple and efficient. Operators can easily adjust parameters, monitor system status in real time, and benefit from password protection and clear maintenance alerts.

Maintains adhesive temperatures between 40°C and 230°C, guaranteeing optimal adhesive performance and preventing charring or degradation.

Supports multiple hoses and applicators (up to 6), making it adaptable to a wide range of production line configurations and easy to integrate with parent machines.

Engineered to work seamlessly with major hot melt brands, making upgrades or replacements straightforward and stress-free.

Available in various melting rate options-4 kg, 7 kg, 10 kg and 20 kg per hour-to meet different production volumes and requirements.

Constructed with heavy-duty, wear-resistant materials for long service life, while its compact footprint allows for easy installation even in limited spaces.

Accessible components, intuitive interface, and robust filtration system minimize downtime and simplify routine maintenance.

Heavy-duty carton and case sealing

Product assembly lines using high-viscosity adhesives

Packaging operations requiring powerful, consistent hot melt application

Woodworking, automotive, and textile industries

Designed to work seamlessly with major hot melt brands, making upgrades or replacements simple and hassle-free.

Available in multiple melting rate options-5 kg, 10 kg, 15 kg, 30 kg, and 50 kg per hour-to suit different production volumes and requirements.

Built with industrial-grade materials for durability and long service life, while its compact footprint allows for easy installation even in limited spaces.

Accessible components, clear interface, and robust filtration reduce downtime and simplify routine maintenance.

I recently purchased a powder coating machine from Smart Engineering and had a great experience. The delivery was impressively fast, and the machine arrived in perfect condition without any damage. I'm very satisfied with their service and product quality—highly recommended!

I recently bought the Electron Series Pro powder coating devices from Smart Engineering. The delivery was prompt, and everything arrived safely without any damage. The product quality is excellent, and the entire experience was smooth. I highly recommend Smart Engineering to anyone looking for reliable powder coating equipment!

Reach out for any inquiries, support, or to discuss how we can meet your industrial needs.

+971 6 525 4214

info@smartengme.ae

Building 58, Office G108 Al Manakh Area, Al Gharb, Sharjah

Landmark: Next to the Everyday Center Building on Main Road

Smart Engineering is your reliable partner for industrial finishing and hot melt dispensing solutions. With more than 15 years of experience, we specialize in supplying, installing, and maintaining powder and liquid coating equipment, as well as hot melt adhesive systems.

Copyright © 2020 – 2025. Smart Engineering. All Rights Reserved.

WhatsApp us